- Témaindító

- #1

- Csatlakozás

- 2023.05.28.

- Üzenetek

- 25,287

- Reakció pontszám

- 551

- Díjak

- 6

- Kor

- 33

File size: 3.80 GB

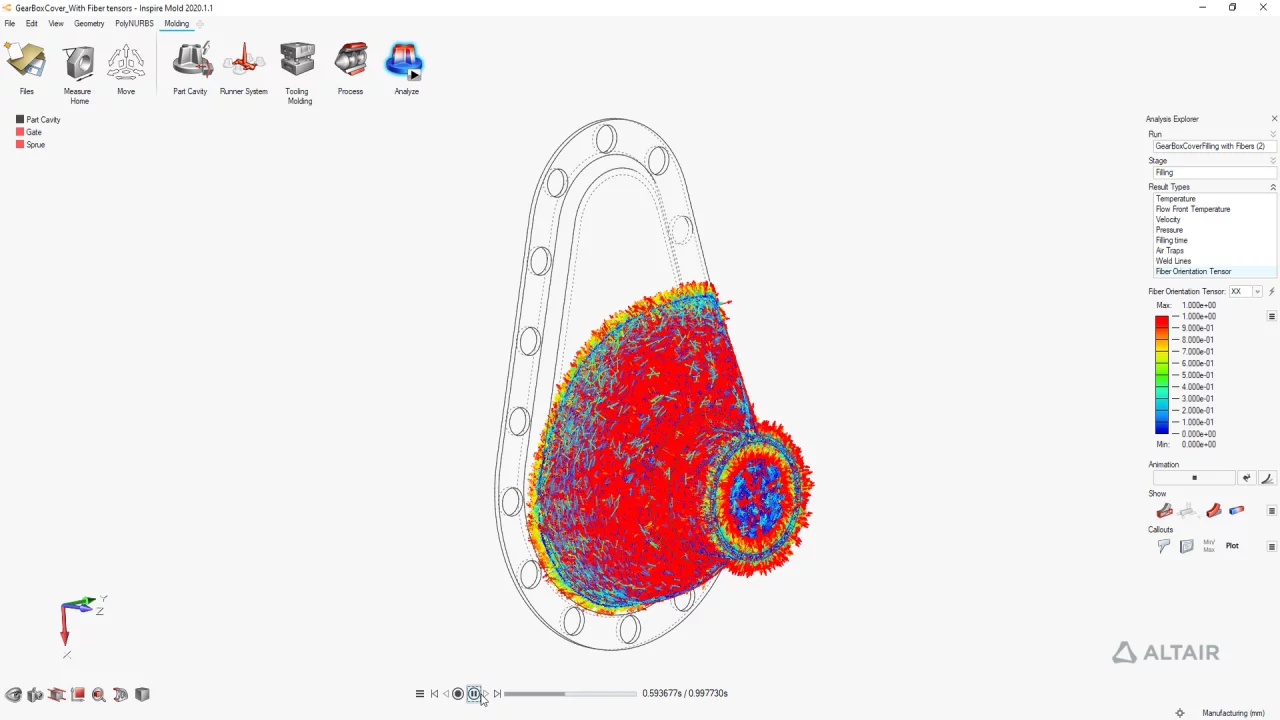

Altair Inspire Mold - a program for modeling plastic injection molding.

Injection Molding Simulation

Injection molding of plastics is an established, proven industrial manufacturing process for the mass production of identical components. Inspire Mold provides a modern integrated approach to streamline design for manufacturing (DfM) of injection molded components. Simulation is finally democratized and placed in the hands of designers and product engineers early in the development cycle, enabling easy exploration of options and delivering improved products, reduced scrap, and tooling rework costs.

Understand how the mold fills with a fast analysis, then dig deeper into the process with a detailed simulation of all the advanced physics.

Virtual testing, validation, correction, and optimization of molding designs can be easily performed through a five-step workflow, providing access to evaluation of injection molded part manufacturability that mitigates common manufacturing defects (warping, sink marks, short shots, etc.) long before a mold is made.

Altair offers a comprehensive set of solutions to develop innovative, manufacturable products faster: from the initial design of the part and understanding the injection molding process, to material mapping of reinforced engineering polymers and efficiently analyzing and optimizing the structural and fatigue performance of complex parts.

Key Features

Generate Mold Design

Build the initial mold starting from a 3D part design, automatically generating geometry for runner systems, gates, vents, and other key mold components.

Mold/Part Configurations

Test and optimize different configurations in seconds, including multiple cavities, mold inserts, sprue, and runner systems.

Advanced Physics

Supported physics include filling, packing, cooling, and warpage simulation.

Defect Prediction

Easily detect typical manufacturing defects such as sink marks, short shots, air traps, weld lines, jetting, and hesitation.

Fiber-reinforced Parts

Simulate fiber orientation and easily apply results to advanced structural analyses of composite materials.

Access to Materials Data

Data for 60 materials is embedded in Inspire Mold and the Altair® Material Data Center™ will soon be integrated, allowing MDC license holders direct, immediate access to reliable, high-quality material data.

Screen :

What's New

Read: InspireMold_2023_0_ReleaseNotes_English.pdf

HOMEPAGE

Code:

⚠

A kód megtekintéséhez jelentkezz be.

Please log in to view the code.

Code:

⚠

A kód megtekintéséhez jelentkezz be.

Please log in to view the code.